240V 380V Ultrafilter Device Plant RO 12000lph Water System

Basic Info

| Model NO. | WY-SW-240 |

| Certification | ISO9001, CCS |

| Salt Rejection Rate | No Less Than 98% |

| Application | Island, Marine Drilling Platform, Tanker, etc. |

| Capacity | 240000 Liters Per Day |

| Product Name | RO 12000lph Water System |

| Voltage | 110~450V ; 50Hz / 60Hz |

| Power | 33kw |

| Main Material | Stainless Steel |

| Operation Pressure | Less Than 6.5MPa |

| Protection Level | IP54 |

| Recovery Rate | 45% |

| Control System | Automatic / Manual |

| Life Span | 15 Years |

| Warranty | 2 Years |

| Transport Package | International Standard Export Package |

| Specification | 40 feet container |

| Trademark | WANGYANG |

| Origin | Zhuhai City, Guangdong Province, China |

| HS Code | 8421219990 |

| Production Capacity | 400 Sets Per Month |

Product Description

240V 380V ultrafilter device plant ro 12000lph water systemRo 12000lph water system

1)Product Description

1.1)Profile Ro 12000lph water system is professionally used in freighter,tanker,drilling platform,island and so on.This kind of equipment will open drain valve automatically to discharge water when the TDS of production water exceed standard value,which provide accurate value. 1.2)Specification

Product Name | Ro 12000lph water system |

Model | WY-SW-240 |

Raw Water | Sea Water |

Water Yield | 240m³/d |

Voltage | 110~450V;50Hz/60Hz |

Power Factor | 33Kw |

Desalination Rate | ≥ 98% |

Recovery Rate | 45% |

TDS of Output Water | <700mg/L |

Operation Pressure | <6.5Mp |

Main Material | SS |

Protection Level | IP54 |

Working Environment Temp | 0~45°C |

Suggest Input Water Temp | 5~45°C |

Working Environment Air Humidity | 20~90% |

Control System | Automatic / Manual |

Dimension | 40 Feet Container |

| Life Time | 15 Years |

Certificate | ISO9001, CCS |

Warranty | 2 Years |

Customized | Available |

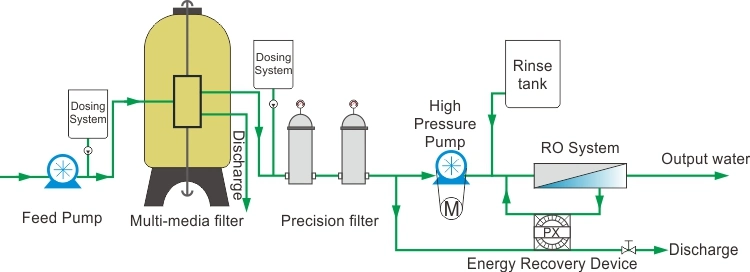

2)Process Info for Ro 12000lph water system

2.1)Feed pump: to provide sufficient pressure for subsequent filtration.2.2)Multimedia filter: It mainly removes the mud, suspended solids and large particles in the water.2.3)Precision filter: further filtration, protection of reverse osmosis membrane.2.4)Energy recovery device: one of the key devices, and it is crucial to drastically reduce the energy consumption and water production cost of the system.2.5)High-pressure pump: provide enough pressure for reverse osmosis system.2.6)RO system: almost all soluble salt, colloid, organics will be removed.2.7)Rinse tank: protect the membrane system without polluted by using chemical agent.

3)Design & Manufacture

| Maintenance space | The front 1000mm, the back 700mm,the left & right each side1000mm. |

| Feed pump inlet | DN65 |

| Concentrated water outlet | DN50 |

| Product water outlet | DN40 |

4)Main Features of Ro 12000lph water system

Reverse osmosis technology is a modern high technology that use reverse osmosis to seperate water from solution after it permeates the specially-made semi-transparent membrane though exerting a pressure that is higher than the osmosis pressure on the solution.According to different osmosis pressure of various materials the process of reverse osmosis with a pressure higher than the osmosis pressure can be used to reach the purposes of separation, extraction, purification and concentration of a certain solution. It saves more energy than traditional process.

4.1)The most advanced RO system and membrane component;4.2)Efficient energy recovery technology;4.3)Adoption of high-quality safety pressure relief device & observation system;4.4)Stable operation & high-quality producing water.

5)Package & Shipment

5.1)PackageRo 12000lph water system is with international standard export package.5.2)ShipmentWe will choose the most suitable shipping way according cistomers' need.

6)Company Information

6.1)Company Profile Founded in 2010,Zhuhai Wangyang Water Treatment Equipment Co,.Ltd. is a high-tech enterprise integrated with R&D,production,selling and engineering installation.Specializing in seawater and brackish water desalination,reclaimed-water recycling, hyper pure water,boiler-feeding water,electroplating metallurgy,we have professional technical team and after-sales team. With continuous innovation and good quality guarantee,we have obtained some certificate like ISO9001,CCS,etc.As well,we have our own patent. We persist in the principle "Customers come first,High-quality service,Excellent product".Integrity is the root of our long-term development while customers' satisfaction is our persistent pursuit.

6.2)Certificate

6.3)Exhibitions

7)Our Services

7.1)Installation & Commissioning As the supplier,we have the responsibility to complete the installation & commissioning for customers before shipment.For customers need,we're available to finish that in customers' requested place. 7.2)Training We will provide clients technical training,which includes equipment structure & maintenance, control & operation. In this way, the technicians of customers can grasp relevant skills after training. 7.3)Quality Assurance & After-sales Equipment mechanical part is given total quality assurance within two years from the equipment installation and commissioning completed acceptance.During the warranty period,our company will arrange technologist to call you and ask about the equipment using situation very quarter.Consumable materials and vulnerable parts which are normal wear and tear are not within the warranty.Outside the quality assurance period,we can also provide comprehensive technical support and maintenance services for customer.

8)FAQ

Q1: Are you manufacturing company or trading company?

A:We're a professional manufacturer for water treatment equipment.And always welcome to visit our factory. Q2: How should I select the plant?

A:It depends on your requested parameters,such as raw water source,water quality,water yield,voltage,etc.

Q3: What's your suggest for maintenance?

A: 1)check all circuit whether damaged; 2)check valve whether malfunctioning phenomenon; 3)check all pipes for leaks; 4)If long time no use,you should add protective solution to protect the reverse osmosis: 4.1)Open inlet which in the front of the high-pressure pump (see illustration), make well the protective solution in the water tank ,then connect with the tank via pipe , start the water tank pump, when the protective solution full filled with reverse osmosis membrane group, turn off the water tank pump, close the inlet. Meanwhile every day to observe, such as protection fluid leakage situation, should replenish the above step. 4.2)Before equipment start-up , protective solution should be clear up.Q4: Could you offer some info about troubleshooting?

A:Our pleasure in doing that. 1)high-pressure pump: Each work 200 hours to inspect, pressure whether normal, whether the crankcase short of oil, the pump whether abnormal and other tests, such as abnormal working, in accordance with the manufacturers instructions for maintenance. If do not have maintenance skills, please timely contact with the manufacturer, we will maintenance for client. 2)booster pump:Maintenance, inspection, refer to the high-pressure pump, the specific details, see the lift pump manual requirements. Equipment failure, if you are able to maintenance and repair, the manufacturer can provide technical support. If do not have skills to repair, made it clear that the cause of the malfunction and fault coverage, please contact the manufacturer.Q5: What's your payment term?

A:PayPal,T/T,Western Union,L/C available;40% deposit before manufacturing,and the rest should be paid before shipment.

9)Advantages of Choosing US

9.1)Our company has obtained ISO9001 quality management system certificate, Inspection certificate of China classification Society(CCS) and the letter of patent for seawater desalination equipment in container.9.2)We are the direct manufacturer. We have our own factory so that we can offer you high quality product with a good price. 9.3)Owning a self brand "WANGYANG" and a professional practical engineer team. 9.4)Total water solution is available.9.5)The punctual delivery of goods, quality and quantity guaranteed.9.6)8 years experience, OEM&ODM available.

10)Contact