SS-NF2-3840 Nano filtration membrane for dairy process / cross: Dupont, FilmTec NF membrane

NF membranes have a molecular weight cut-off between 150-2000 Dalton usually. RisingSun Membrane manufacture spiral sani;

Basic Info

| Membrane Type | Spiral |

| Type | NF |

| Membrane Sheet | NF245 |

| Feed Spacer | 31mil |

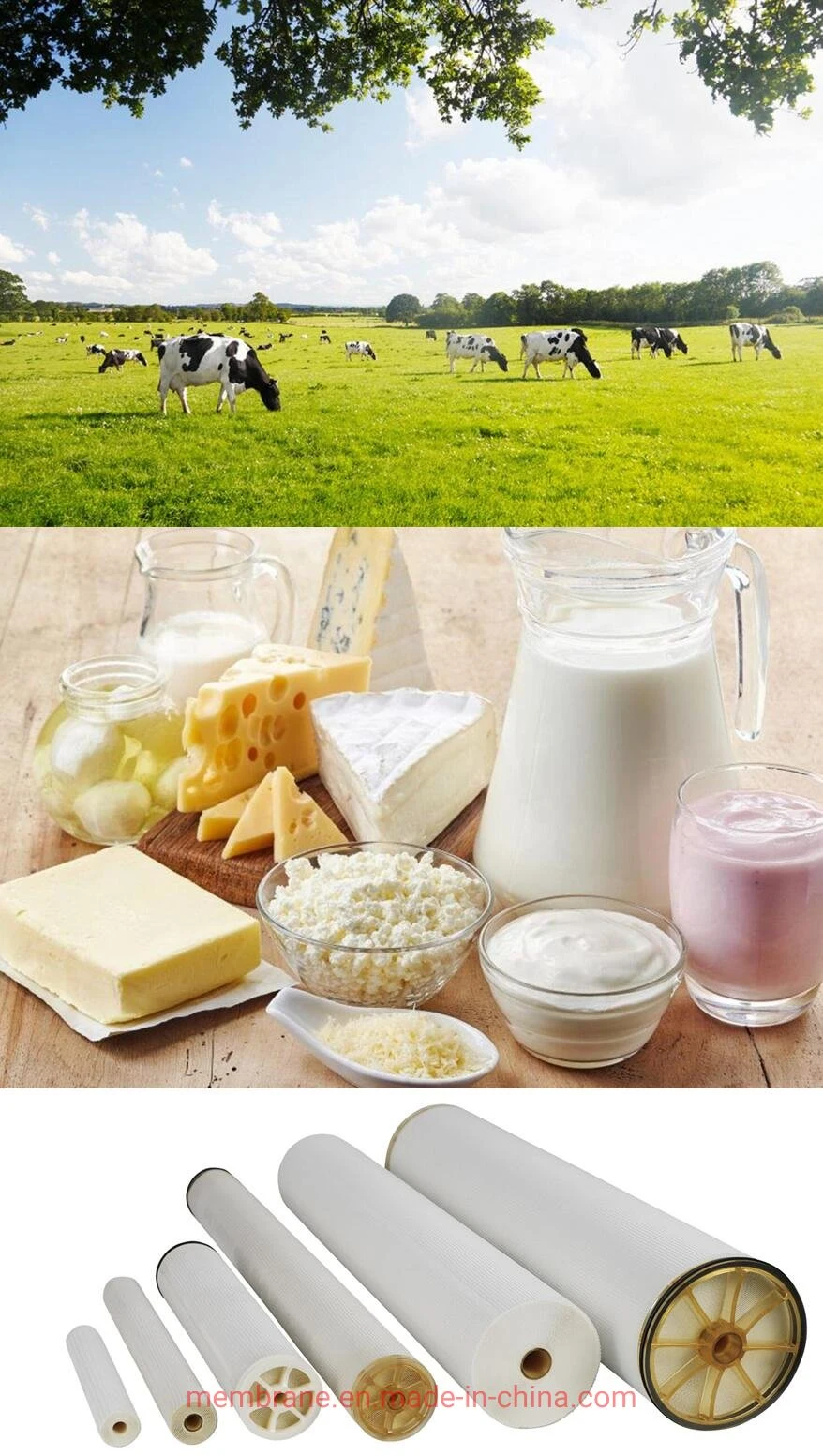

| Application | Dairy Processing |

| Cross Replacemnt | DuPont / Filmtec NF-3840/30-FF |

| Outer style | Mesh Wrap Full Fit |

| Transport Package | Carton/Pallet |

| Specification | 3840 |

| Trademark | RisingSun |

| Origin | China |

| HS Code | 84219990 |

| Production Capacity | 500piece / Month |

Product Description

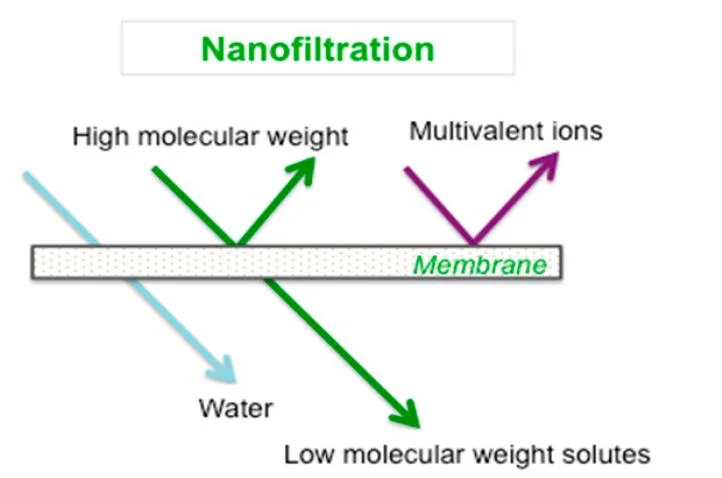

NF membranes have a molecular weight cut-off between 150-2000 Dalton usually. RisingSun Membrane manufacture spiral sanitary, Net-Wrapped NF membrane elements for food process, such as dairy, for simultaneous concentration and partial (monovalent ion) demineralization, Biotec, Pharma, and other applications.RisingSun Membrane Nanofiltration cross replace Dupont / DOW/ Filmtec NF membrane.

We offer different dimensions, such as 3838/3840/ 6338/8038/8040/8338 etc. Full-Fit NF Membrane Elements. They have a compact design and an optimum surface area to volume ratio. The feed channel height can be varied by the thickness of the feed spacer material (from 13 to 120 mil). This design feature leads to excellent hydrodynamics in combination with low energy demand.

Demineralization and concentration

NF separates a range of minerals from a liquid, allowing only the fluid and certain monovalent ions to pass through the membrane.The membrane has a minimum rejection of 98% on 2,000 ppm MgSO4 at 25°C (77°F) and 110psi operating pressure.The Dairy Processing Elements are typically used in food related processes requiring stringent sanitary procedures. Applications include lactose desalting, deacidification and demineralization of whey or UF permeate.

Decoding of our products codes: SS-NF2-3840-F (Alternative FilmTec NF-3840/30-FF)

| Configuration | Outer Wrap | Membrane Type | Size | Feed Spacer | |

| SPIRAL | SANITARY | NF245 | 2319 2.3"×19" | A=13mil | F=31mil |

| 3840 38"×38.75" | B=17mil | G=46mil | |||

| 3838 3.8"×38" | C=20mil | H=65mil | |||

| 6338 6.3"× 38" | D=26mil | I=80mil | |||

| 8038 8.0"× 38" | E=28mil | J=120mil | |||

| ... | 1=Diamond | 2=Parallel | |||

Specifications:

| Typical Operating Pressure: | 70-400 psi (4.8-27.5 bar) |

| Maximum Operating Pressure: | 800 psi (54.8 bar) |

| Maximum Operating Temperature: | 122°F (50ºC) (pH:3-10) |

| 95°F (35ºC) (above pH 10) | |

| Typical Operating Temperature Range: | 35-131°F (2-45ºC) |

| CIP Temperature Range: | 113°F (45ºC)-pH:1.8-11.2 |

| 122°F (50ºC)-pH:1.8-11 | |

| Maximum CIP Pressure | 15 - 75 psig (1 - 5 bar) |

| Allowable pH-Continuous Operation @25ºC: | 2.0-11.0 |

| Maximum Feed Flow: | 30GPM (F); 36 GPM(G) |

| Maximum Pressure Drop Per Element: | 15 psi (1.0 bar) |

| Maximum Pressure Drop per Vessel: | 60 psi (4.1 bar) |

| Maximum SDI ( 15 minutes): | 5 |

| Hydrogen peroxide usage limit: | Short-term cleaning (@ 25°C maximum): 1000PPMdechlorination recommended |

| Any concentrate or permeate obtained from the first hour of operation should be discarded. | |

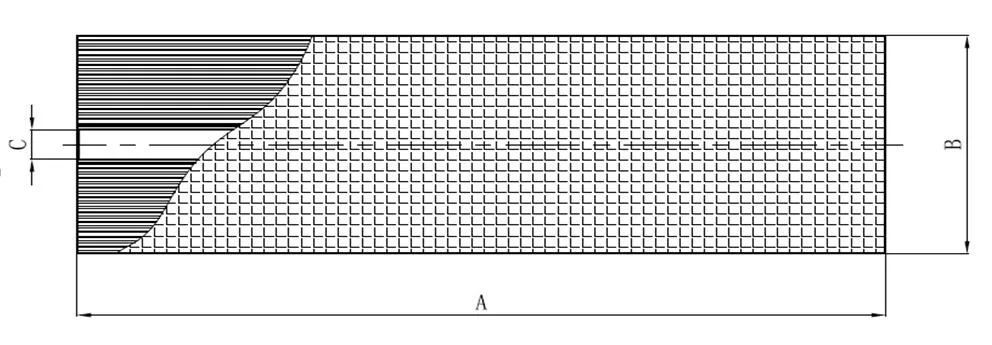

Dimensions:

| Model | A (inch) | B (inch) | C (inch) |

| NF-3838 | 38 | 3.8 | 0.83 |

| NF-6338 | 38 | 6.3 | 1.138 |

| NF-8038 | 38 | 7.9 | 1.138 |

| NF-3840 | 38.75 | 3.8 | 0.83 |

Applications:

Why us?

We brings a knowledge-based approach to the supply of membrane products for dairy processing.Our most important resource is our staffs, who have years of combined experience in dairy membrane filtration and process technology.For raw material, we use the highest quality raw material from USA.All raw materials in compliance with FDA regulations (CFR) Title 21Automatic rolling machine to keep the steady good performance.To start business, we offer free testing samples to help you understand well.

Our Team

You may also like

Send inquiry

Send now